Quality! Price! Delivery!

We will do our utmost

100% to satisfy

our customers

Company which keeps

moving forward and trying

harder and harder...

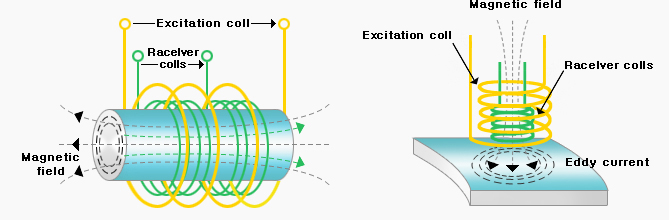

Test methods are used to measure the degree of rigidity of metallic materials.

The typical method is as followings :

Tension test is taken after being fixed on a tensile tester, which is cut down from the material to the test. This test measures a variety of points of the material, such as the Strength – Tensile strength and kidney – drawing, and mechanical properties of tensile specimen after loading slowly.

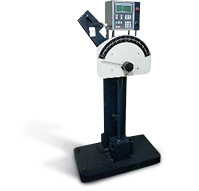

There are various tester to obtain shock points when breaking materials such as tension ,

compression, bending test, the test shock applied to the specimen using metal tester.

Representative tester is for the degradation of impact bending test.